Investing in efficiency to secure the project and its operational profitability

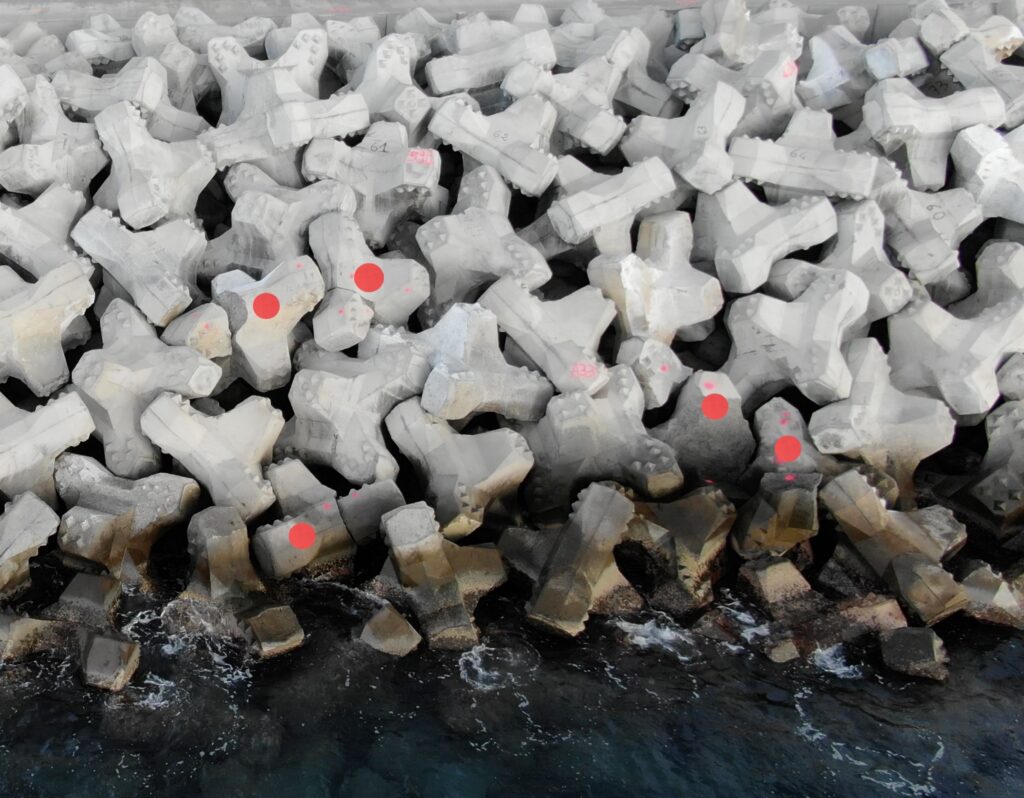

CLAS has chosen to establish specialized placement teams, bringing together maritime construction experts and professional divers specifically trained in single-layer artificial concrete armour unit technologies with high interlocking performance.

Each team member benefits from an internal CLAS training program, covering all artificial concrete armour units used for breakwater armour layers, across all brands, generations and configurations.

This offering responds to a clearly expressed need from maritime contractors and project owners, in a context where public procurement requirements are evolving and increasingly incorporate feedback from recent construction projects.

Experience gained on numerous projects shows that certain modern technologies, when used without in-depth analysis of their operational validity conditions, may lead to gaps between theoretical assumptions and on-site reality.

These situations are not linked to an intrinsic flaw in single-layer technologies, but most often result from a lack of understanding of their limits of use, or from an absence of direct and continuous control during the installation of artificial concrete armour units.

When these limits are not correctly identified, the consequences may become visible after the structures are commissioned, sometimes relayed by the media, and may lead to misinterpretations regarding the reliability of single-layer systems, even though these systems above all require impeccable installation quality and appropriate control.

The Project Action Chain for Single-Layer Breakwaters: From Technology Selection to On-Site Implementation

In a typical single-layer breakwater project, the project workflow follows a well-established sequence:

– the Client / Owner appoints an Engineer in charge of design, construction supervision and works acceptance,

– the Engineer develops the breakwater design and prepares the tender documents,

– the call for tenders specifies concrete armour unit technologies in the form “ACCROPODE™ II or equivalent”, “Xbloc® or equivalent”, “CORELOC™ or equivalent”, in accordance with public procurement regulations requiring technical equivalence when brand names are cited for reference purposes,

ACCROPODE™ is a trademark owned by the ARTELIA Group and marketed by its subsidiary CLI.

Xbloc® is a registered trademark owned by BAM.

CLAS is in no way affiliated with either of these companies and intervenes on site after a licence agreement has been formalised when one of these trademarked systems is selected by the contractor for the project on which CLAS acts as a subcontractor.

– the maritime contractor then selects, according to its strategy, the services required and the contractual context, either a branded system under licence, or a royalty-free solution derived from patents that have expired.

In all cases, the contractor may rely on CLAS for on-site operational support, in addition to any services provided by licence holders, who are neither divers nor maritime construction specialists and do not take part in the actual installation of the armour units on site.

A CLAS diving team specialised in the installation of ACCROPODE™ II, CORELOC™ or Xbloc® typically places and validates an average of 8 approved units per hour.

Client testimonials and our project references by armour unit type provide documented evidence of this performance.

The CLAS installation team works with the contractor to define site-specific safety procedures and supports the placement of concrete armour units with a level of productivity and quality control that cannot be achieved without dedicated specialists.

This execution speed significantly limits the exposure of the underlayer and core to wave action, reduces the risk of premature damage, and avoids costly dismantling operations resulting from the late detection of non-compliances.

The time saved thanks to CLAS diver-based installation teams translates directly into improved contractor productivity and overall project cost savings that largely exceed the cost of CLAS intervention.

Understanding the real requirements of single-layer breakwater armour systems

Experience gained on numerous international projects shows that the construction of a breakwater with a single-layer armour made of highly interlocking artificial concrete blocks allows no approximation.

The rules of good practice, as defined by international references (Rock Manual / CEREMA Rock Armour Guide), recall a fundamental principle:

single-layer armour layers are designed for zero damage, including during severe wave events.

In this context, installation quality, effective interlocking of the blocks, and immediate control of non-conformities are decisive factors for the long-term stability of the structure.

Why a specialized team is essential

This technical reality requires a specific site organization.

It calls for a dedicated operational tool, capable of intervening as close as possible to the placement operations, both on the surface and underwater.

It is on the basis of this observation that CLAS has developed a unique approach:

👉 specialized placement teams, directly integrating:

professional divers trained in the installation and inspection of single-layer artificial concrete armour units,

maritime construction experts mastering the geometric, hydraulic and operational constraints of highly interlocking armour layers,

This organization makes it possible to act at the moment when decisions are still reversible, block by block, without waiting for deferred validations.

Technical independence and absence of conflict of interest

CLAS operates in full independence with respect to trademark holders, license vendors, and suppliers of placement and inspection tools.

This independence is a key element of the credibility of CLAS interventions.

It ensures that analyses, recommendations and on-site decisions are based exclusively on:

the rules of good practice applicable to maritime breakwaters,

direct observation of on-site reality,

the technical and economic interest of the project.

It is within this framework that CLAS has been called upon to carry out independent expert assessments, identify the causes of disorders observed on certain structures, and ensure supervision of remedial works when required.

Safety, hyperbaric operations and operational control

To meet the requirements of the most complex projects, CLAS has developed its own underwater intervention capabilities and has become a company certified for hyperbaric operations.

CLAS teams:

include IMCA- and HSE-certified divers,

master modern industrial diving equipment,

apply strict safety procedures and coordination with lifting teams.

Safety is not treated as an administrative constraint, but as a performance lever, making it possible to ensure operational continuity, reduce uncertainties and secure schedules.

Site organization and risk control

Experience shows that advancing the core or the underlayer of a structure without immediate protection by armour units constitutes a major risk, often underestimated.

An unprotected structure remains exposed to the first significant storm, with possible consequences such as:

partial destruction of the works in progress,

loss of achieved progress,

accumulated delays and significant cost overruns.

CLAS teams support contractors in the definition of realistic site strategies, adapted to the site conditions, available resources and scheduling constraints, in order to secure each critical phase of construction.

A profitable investment for contractors

Calling on a CLAS team does not represent an additional expense, but a directly profitable investment.

The presence of specialized teams makes it possible to:

limit costly dismantling and rework operations,

improve actual on-site productivity,

reduce technical and contractual risks,

secure the final quality of the structure.

This approach contributes to better overall economic control of the project, while guaranteeing the technical compliance of maritime breakwater armour layers.

Choosing a CLAS team means choosing:

operational safety,

impeccable installation quality,

control of technical risks,

and sustainable project profitability.

CLAS supports maritime contractors with a pragmatic, independent approach, grounded in real on-site experience.