Independent expertise, regardless of the technology or armour unit brand used

CLAS expertise serving quality and long-term durability

For more than thirty years, CLAS (Concrete Layer Assistance & Survey) has been supporting the installation of single-layer artificial concrete armour units for the construction of breakwaters and port structures.

Our objective is to ensure the stability, compliance and long-term durability of maritime structures, regardless of the type or brand of armour units used.

The success of a breakwater project primarily depends on the accuracy of placement operations and the quality of block interlocking.

CLAS provides contractors and project owners with comprehensive operational support, combining training, on-site supervision and quality control, to ensure compliance with international standards and recognised construction best practices.

Support tailored to on-site construction realities

On site, the success of a breakwater project does not depend solely on the choice of an armour unit or the signing of a licence agreement.

It primarily depends on the ability to place the armour layer correctly and efficiently, in order to protect the underlayer, control construction schedules, and secure the technical and financial objectives of the project.

When it becomes essential to move fast

When the installation rate becomes insufficient, when the underlayer remains exposed for too long, when delays accumulate or when acceptance of the works remains uncertain, technical and economic risks increase rapidly.

It is precisely in these situations that CLAS’s intervention makes the difference.

For more than thirty years, CLAS has supported contractors and owners beyond contractual frameworks, by providing independent operational expertise, applicable to all brands and technologies of single-layer concrete armour units.

Avoiding costly remedial works and penalizing delays

Our role is not to sell a solution, but to secure the actual execution of the structure, in real time.

By combining on-site installation assistance, team training, continuous supervision and in-situ quality control, CLAS makes it possible to anticipate deviations, correct discrepancies before they become irreversible, and ensure the final conformity of the structure.

Leveraging experience to secure the successful delivery of the project

👉 Experience shows that it is better to intervene early than to repair later.

CLAS is there to guarantee the stability, durability and successful completion of the project, whatever the technology or the brand of blocks used.

The success of a breakwater construction project depends above all on the accuracy of placement and the quality of block interlocking. CLAS provides companies and project owners with comprehensive operational support, combining training, supervision and quality control, to ensure compliance with international standards and good construction practices.

When initial training no longer meets the company’s operational needs

When the initial training provided by licence vendors is limited to a presentation of technical documents and a few exercises on scale models, it may not be sufficient to fully prepare teams for the operational demands of a single-layer armour unit project.

In such situations, teams do not necessarily have the level of experience required to ensure proper interlocking underwater, to immediately identify non-conformities, or to maintain a steady production rate.

Depending on the project, this can lead to interlocking errors, non-conformities detected too late, more extensive dismantling than initially planned, and delays impacting both the project schedule and construction costs.

Operational expertise, directly integrated into construction

Conversely, CLAS provides comprehensive and independent assistance, dedicated to the construction process itself.

Our teams are present on site full time, both above and below water, with:

professional divers specialized in the placement of single-layer armour units,

continuous supervision of each block placed,

daily hands-on training directly integrated into installation operations,

immediate quality control, with instant correction of any placement defects.

This exclusive operational support makes it possible to achieve qualitative and production performance levels that no other method can match.

Support that guarantees results

Some commercial offers rely on procedures that are comfortable for service providers, but sometimes poorly suited to the operational reality of a single-layer armour unit breakwater construction site.

In these approaches, the assistance provided is often limited to the transmission of digital files and technical documents, without direct involvement in the construction process.

These methods are mainly based on:

multibeam sonar surveys,

long acquisition campaigns over large areas,

complex post-processing,

heavy numerical modelling,

and analysis lead times frequently exceeding 48 hours.

In practice, these tools cannot be mobilised for just a few blocks:

the surveys are only carried out after several rows have been placed, once the armour layer has already progressed significantly.

As a consequence:

when the interpretation finally becomes available, the construction site has already advanced by several days.

If a non-conformity is detected at that stage, the contractor must then:

dismantle several rows,

rebuild them,

and accept a high risk of repeating the same errors,

since the next inspection will only take place several days later.

This type of delayed procedure contributed to the technical and financial disaster of the Nouvelle Route du Littoral (NRL) breakwaters.

Since then, French contracting authorities have thoroughly reviewed their requirements and now impose the presence of professional divers for direct, block-by-block monitoring.

Another important point: these digital solutions are not 100% reliable.

It is common to observe:

real non-conformities that are not detected,

non-existent non-conformities that are nevertheless reported, as observed at Port Gardian.

Inaccuracies in sonar data or numerical models lead to erroneous interpretations that disrupt construction progress for no valid reason.

By contrast, CLAS has always ensured an immediate, real-time control, directly underwater, carried out by professional divers present full-time on site.

This method:

detects each non-conformity at the exact moment it appears,

allows immediate correction,

avoids massive dismantling operations,

guarantees stable and compliant interlocking,

secures production rates, quality and deadlines.

Today, this is the only approach that is truly operational and adapted to the construction of single-layer armour unit breakwaters.

Here, on the AL ZOUR construction site in Kuwait, we see a CLAS inspector training the divers directly through hands-on work. In this case, the safe removal of a broken CORELOC block.

A comprehensive three-module training programme to master armour unit placement

Safety training

Safety is integrated into the project HSE programme and covers:

– the specific risks associated with breakwaters built with artificial concrete armour units,

– coordination between divers and crane operators,

– lifting operations and signalling safety,

– above-water operations.

le travail en immersion.

L’ensemble des personnes concernées par la pose des blocs de carapace et l’accès à la zone de pose reçoit cette formation.

Quality training

This module trains teams to identify non-conformities, read placement drawings, apply geometric tolerances, and ensure proper interlocking underwater.

Production training

Once safety and quality are under control, teams learn to achieve high production rates without dismantling:

– 8 blocks per hour validated under normal conditions,

– up to 15 blocks per hour under optimal conditions.

Essential presence of professional divers

A requirement of public procurement contracts

Several major projects carried out without the presence of professional divers to guide and validate the placement of artificial armour units have encountered significant difficulties.

On the DAS ISLAND project in Abu Dhabi, CLAS inspectors had to manage the partial removal and reconstruction of 4,500 metres of Xbloc® armour layer, due to placement operations carried out and controlled exclusively using the ECHOSCOPE® system.

Only divers trained and supervised by CLAS inspectors were able to restore the situation.On the BARAKAH project in Abu Dhabi, CLAS inspectors had to manage the partial removal and reinstallation of several thousand CORELOC units, following placement and control operations performed exclusively using the POSIBLOC™ system.

Once again, divers trained and supervised by CLAS inspectors resolved the situation.On the NRL project on Réunion Island, damage occurred on the ACCROPODE™ II armour layers of all four breakwaters, due to placement operations essentially carried out using the POSIBLOC™ tool, validated on the basis of multibeam surveys and digital tools.

Here again, professional divers dismantled and correctly reinstalled several thousand units under CLAS supervision.More recently, on the Port-la-Nouvelle project, the company BOUYGUES was unable to construct the offshore breakwater fast enough, which was destroyed three times by storms.

The procedures relied on POSIBLOC™-based placement and validation using multibeam surveys and numerical models.

BOUYGUES ultimately called upon a full CLAS team, which completed the offshore breakwater protection in two months, with the support of specialised divers.

ACCROPODE™ is a registered trademark belonging to the ARTELIA Group.

POSIBLOC™ is a registered trademark belonging to the company MESURIS.

ECHOSCOPE® is a registered trademark belonging to the company CODAOCTOPUS.

These companies are in no way affiliated with CLAS.

CLAS is totally independent from these companies and brands and operates differently, notably by systematically deploying professional divers to support contractors on site.

In light of this accumulated experience, engineers and contracting authorities now require rigorous underwater inspection and control.

This evolution establishes CLAS practices as the technical standard for the construction of single-layer concrete armour breakwaters.

Recent public tenders in France

Requirement of SUEZ, Engineer in charge of design, construction supervision and works acceptance, on the Argelès-sur-Mer site for the installation of artificial concrete armour units

3.4.11 Start of placement operations

The installation of the blocks shall be carried out “using highly precise construction equipment guided by a 3D GPS positioning system and by divers.” The accuracy of the positioning systems and of the placement method shall comply with the requirements of the certifying body for ACCROPODE artificial concrete armour units or equivalent.

(ACCROPODE™ is a registered trademark belonging to the ARTELIA group, which is in no way affiliated with the company CLAS)

Requirement of SUEZ, Engineer in charge of design, construction supervision and works acceptance, on the Argelès-sur-Mer site for the installation of artificial concrete armour units

3.4.9.2 Control and approval requirements for the artificial concrete armour layer

The objective is to prevent movements of the blocks after placement, which may result in breakage and extraction of units leading to premature damage of the armour layer.

The inspection body shall demonstrate recognized expertise in the construction of breakwater armour layers and in control and inspection activities, and shall present at least five reference projects less than five years old, involving at least three different types of artificial concrete armour units.

The personnel in charge of inspection shall mandatory hold professional diver qualifications with valid and current certificates. Any inspection agent or inspector authorized to validate the documents submitted to the Engineer in charge of design, construction supervision and works acceptance shall be able to demonstrate having acted as an inspection agent or inspector on at least three breakwater armour layers constructed with artificial concrete armour units, including at least two projects involving the same type of unit as specified in the works contract.

Requirement of BRL, Engineer in charge of design, construction supervision and works acceptance, on the La Turballe site for the installation of artificial concrete armour units

3.6.3.2. PLACEMENT ASSISTANCE

The contractor shall implement all placement assistance means necessary to comply with the placement drawings and the installation rules specified by the block distributor.

This assistance may be carried out using electronic monitoring systems. It shall be mandatory supplemented by professional divers trained in the installation of the blocks.

Requirement of EGIS, Engineer in charge of design, construction supervision and works acceptance, on the Port Gardian site for the installation of artificial concrete armour units

6.9.7 Installation of artificial concrete armour units

The installation of the blocks shall be carried out “using highly precise construction equipment guided by a 3D GPS positioning system and by divers.” The accuracy of the positioning systems and of the placement method shall comply with the requirements of the certifying body for X-BLOC artificial concrete armour units or equivalent.

(X-Bloc® is a registered trademark belonging to DMC, which is in no way affiliated with the company CLAS)

Requirement of EGIS, Engineer in charge of design, construction supervision and works acceptance, on the Port Gardian site for the installation of artificial concrete armour units

6.9.6.2 Control and approval requirements for the artificial concrete armour layer

The objective is to prevent movements of the blocks after placement, which may result in breakage and extraction of units leading to premature damage of the armour layer.

The inspection body shall demonstrate recognized expertise in breakwater armour layer construction and in control and inspection activities, and shall present at least five reference projects less than five years old, involving at least three different types of artificial concrete armour units.

The personnel in charge of inspection shall mandatory hold professional diver qualifications with valid and current certificates. Any control agent or inspector authorized to validate the documents submitted to the Engineer in charge of design, construction supervision and works acceptance shall be able to demonstrate having acted as a control agent or inspector on at least three breakwater armour layers constructed with artificial concrete armour units.

Missions carried out by CLAS divers

Underlayer inspection

Before any placement operation, the underlayer is visually inspected underwater, as closely as possible, in order to verify:

the actual gradation,

the continuity of the supporting layer,

the roughness required for proper interlocking,

the absence of abnormal voids,

the absence of isolated rocks that could hinder placement.

In the event of an obstacle (out-of-tolerance block, hole, isolated rock),

➡️ rectification is carried out immediately by a diver, even before placement begins.

No delay. No subsequent dismantling.

This guarantees a compliant supporting layer, allowing placement to proceed without abnormal difficulties.

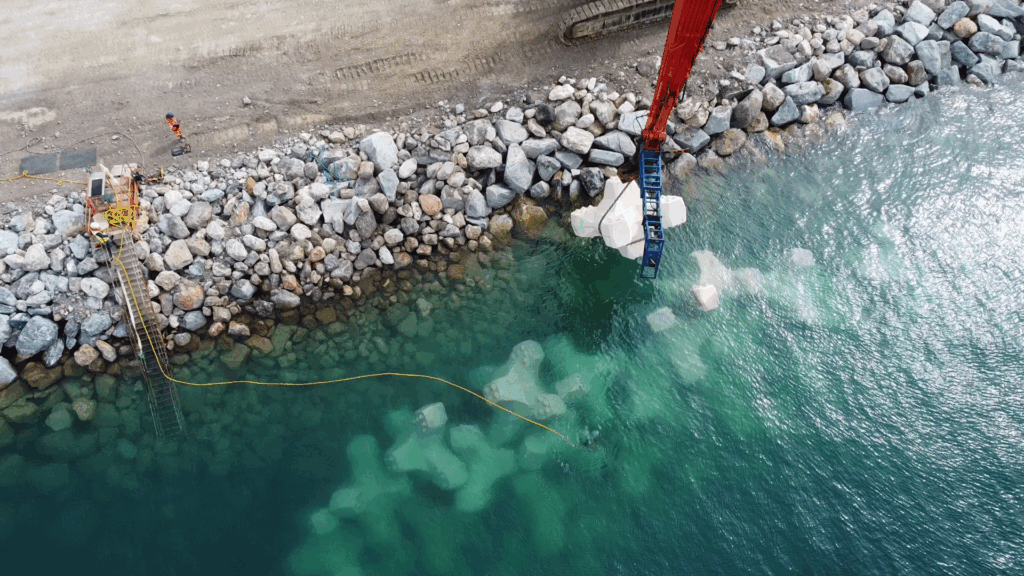

The diver guides the placement of the blocks with precision

CLAS monitors the placement block by block, in real time:

the diver positions the unit, guides the crane operator, validates interlocking, and immediately detects any non-conformity.

If a defect is identified, only the block concerned is repositioned, without dismantling the section — unlike digital controls carried out several days after placement.

Each validated section is fully filmed, constituting:

– proof of compliance,

– a self-inspection support,

– an indisputable reference in the event of third-party observations.

If an “apparent” non-conformity is reported by sonar or a digital model, CLAS video records make it possible to rule out any unjustified dismantling.

In case of doubt, CLAS carries out a filmed adversarial inspection, on site and underwater, allowing the situation to be clarified immediately, avoiding work stoppages and ensuring transparency.

Once underwater placement has been validated, the toe berm is installed, under continuous supervision by CLAS divers. This stage governs the stability of the armour layer and the progress of above-water works.

Above-water placement and inspection by aerial drone

Once the submerged part has been validated, above-water placement can begin.

CLAS ensures:

– visual inspection as works progress,

– regular inspection using aerial drones,

– validation of each above-water row,

– immediate detection of any placement defect.

🟩 Crest placement monitored as works progress

When the armour layer reaches the crest, constraints change.

CLAS carries out:

– block-by-block drone inspection,

– detailed analysis of the final interlocking,

– continuous validation of the last elements of the armour layer.

High production without dismantling

Two simple and essential rules

The performance of a single-layer armour unit project is based on two essential elements:

comprehensive training and a placement method that avoids dismantling.

CLAS has mastered both aspects for more than thirty years, which explains the high production rates and the long-term stability of the structures on which we operate.

Continuous, hands-on training combining theory and practice

The performance of a single-layer armour unit project relies on two essential elements:

comprehensive training and a placement method that avoids dismantling.

CLAS has mastered both aspects for more than thirty years, which explains the high production rates and the long-term stability of the structures on which we operate.

This photograph was taken during the safety training session delivered by CLAS for the construction of the Martigues breakwater, and provided to all personnel involved on the site.

To place units quickly and correctly, personnel must first be:

trained in safety, trained in reading placement drawings, trained in correct interlocking underwater, and trained to immediately recognize non-conformities.

This learning process cannot be achieved in just a few days.

It requires:

time, appropriate training tools (models, videos, photographs, feedback from experience), daily operational supervision,

and the presence of specialized inspectors.

CLAS devotes several weeks to this progressive learning process, until the teams become genuinely autonomous.

Avoiding dismantling: the key to high performance

The massive dismantling operations, following interlocking defects on the ACCROPODE™ II armour layers of the four NRL breakwaters on Réunion Island, caused delays and financial losses of colossal magnitude, widely reported by the media. CLAS intervened on this project to identify the causes of the damage, carry out the risk study, recommend solutions, and supervise the repair works.

This photograph illustrates the impact of a single dismantling and reinstallation operation. There were dozens of such operations on this project. Avoiding these situations is the key to the success of a construction site.

ACCROPODE™ II is a registered trademark belonging to the ARTELIA group, which is in no way affiliated with the company CLAS. It was precisely this independence that was sought for this project and led to the selection of CLAS, in order to avoid conflicts of interest.

High production can only be achieved if:

the blocks are correctly placed right the first time,

non-conformities are corrected immediately,

the armour layer does not have to be dismantled several days later.

CLAS procedures and continuous underwater inspection eliminate massive dismantling operations, which are the primary cause of:

loss of production, extended schedules, increased costs, and repeated errors resulting from the implementation of unsuitable procedures.

This is why projects supervised by CLAS have experienced no failures, no delays, and no conflicts.

Observed performance under real-site conditions

The figures below are taken exclusively from real projects supervised by CLAS, taking into account:

actual placement time, immediate inspections, underwater corrections, and successive validations.

⚠️ Downtime due to equipment breakdowns is not included, in order to compare human and methodological performance only.

Average CLAS-approved production in water with good visibility

| Placement method | Crane | Excavator |

|---|---|---|

| Divers | 6 | 12 |

| POSIBLOC™ | 3 | 3 |

| ECHOSCOPE® | 4 | 6 |

| ECHOSCOPE® + Divers | 6 | 8 |

Average CLAS-approved production in water with low visibility

| Placement method | Crane | Excavator |

|---|---|---|

| Divers | 4 | 6 |

| POSIBLOC™ | 3 | 3 |

| ECHOSCOPE® | 4 | 6 |

| ECHOSCOPE® + Divers | 6 | 8 |

These values have remained stable since 2009, the date of the first comparative studies, and have been confirmed on multiple projects, covering all types of artificial concrete armour units used for single-layer breakwater armour.

For comparison, reference can be made to the production indicated by EGIS on NRL breakwater D4 on Réunion Island, where the average was 3 blocks per hour, prior to rectification of non-conformities.

POSIBLOC™ is a registered trademark owned by the company MESURIS.

ECHOSCOPE® is a registered trademark owned by the company CODAOCTOPUS.

These companies are in no way affiliated with CLAS. CLAS is a fully independent company, independent from historical license vendors and their partners.

How CLAS consistently achieves these performance levels

CLAS combines:

🔵 real-time underwater inspection,

🔵 immediate correction of non-conformities,

🔵 “one-shot” placement without dismantling,

🔵 continuous supervision by professional divers,

🔵 procedures adapted to the actual site conditions,

🔵 integration of local teams,

🔵 a methodology proven on more than 50 international projects.

This approach guarantees:

🟢 high production rates from the very first rows placed,

🟢 impeccable structural quality,

🟢 controlled schedules,

🟢 reliability recognized by contractors and owners.

The three CLAS intervention modes available to contractors

A CLAS consultant supports your teams

This photograph was taken during the safety training session delivered by CLAS for the construction of the Argelès-sur-Mer breakwater, involving the installation of BS2 blocks.

Integrating a CLAS expert at the heart of your placement team means benefiting from a level of expertise that is rarely mobilized on a maritime construction site.

An IMCA- and HSE-certified professional diver, fully fluent in English, he secures every dive operation, improves production reliability, and ensures flawless accuracy from the very first rows placed.

In the event of difficulty or a sensitive situation, he can intervene directly and place the blocks himself, ensuring continuity of production and control of critical stages.

He also implements the full set of CLAS quality certification procedures, ensuring rigorous monitoring, immediate validation, and full traceability of the structure.

A true operational partner, he streamlines decision-making, reinforces site confidence, and enables the contractor to maintain full control of operations while relying on internationally recognized expertise.

Build a mixed CLAS–Contractor team

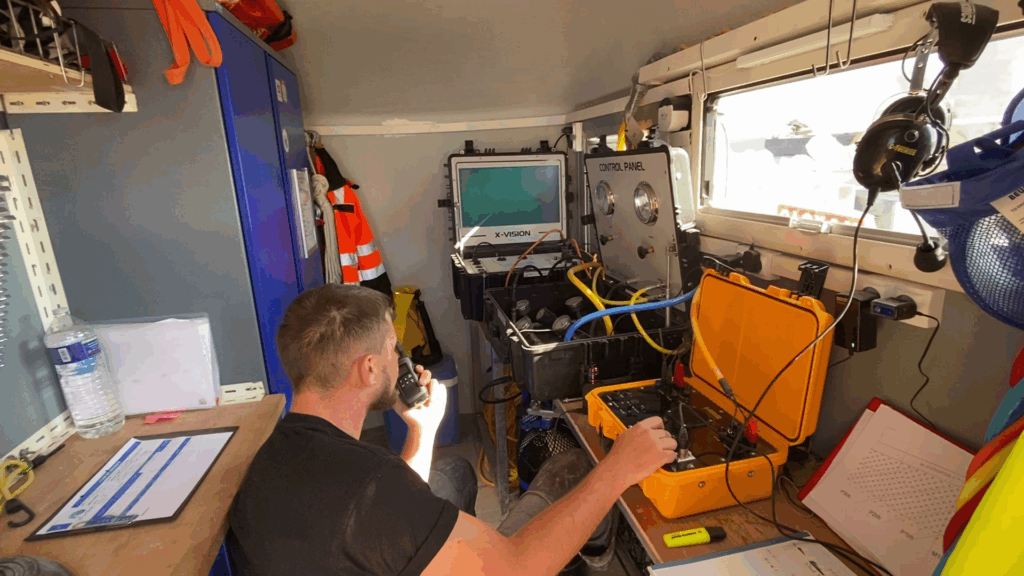

IMCA- and HSE-compliant industrial diving equipment: helmet, communication system, harness, underwater tools, air supply lines and emergency devices. Essential to ensure diver safety during block placement operations.

This approach combines CLAS expertise with the contractor’s professional divers. It enables a rapid increase in production and ensures structural stability from the very first rows placed.

To be fully effective, it requires that the contractor’s divers are proficient in modern industrial diving equipment and hold IMCA and HSE certifications, thereby ensuring a level of safety and professionalism in line with international standards.

Call on a CLAS team

CLAS intervened at Port-la-Nouvelle with immediate responsiveness and a high level of requirements: IMCA/HSE-certified divers, supervisors, continuous inspection and quality control, ensuring safe placement within an extremely short timeframe.

CLAS provides a complete team including IMCA/HSE-certified professional divers, inspectors, supervisors and drone pilots. This configuration immediately delivers maximum safety, full responsiveness in emergency situations, and high production rates, even under difficult conditions.

It is the fastest and safest solution to secure schedules and guarantee full compliance from the very early stages of the project.

For the contractor, this is not an expense: it is a sound investment. The time savings, reduced stoppages, risk control and achieved quality more than offset the cost of the setup.

By combining expertise, operational safety and production performance, this option represents the most attractive commercial solution for any demanding maritime construction project.

Choosing CLAS assistance means guaranteeing your teams’ freedom of action, the highest level of safety, and controlled production.

It means achieving uncompromising execution quality and a faster, more reliable and more profitable project.

CLAS: performance, safety, quality — without compromise.