Identifying, classifying and controlling the real risks of single-layer armour systems

Risk studies applied to maritime breakwaters using single-layer artificial armour units aim to identify situations likely to compromise the stability and durability of structures, beyond purely theoretical or documentary checks.

These studies are based on the analysis of real installation conditions of the artificial blocks, their effective interlocking, their interaction with the underlayer, and their behaviour under wave action.

They make it possible to detect, classify and prioritise non-conformities that may evolve into structural disorders.

The objective is not to challenge single-layer armour technologies, but to control their real risks through a technical approach grounded in field experience, direct observation, and analysis of the stability mechanisms specific to breakwaters built with artificial armour units.

Field-proven expertise dedicated to single-layer armour systems

The approach developed by CLAS for risk studies on breakwaters built with artificial concrete armour units is based on direct and continuous experience gained on maritime construction sites. It has been developed through expert appraisal, technical assistance and inspection missions carried out on single-layer armour systems exposed to a wide range of wave conditions, often severe.

From the very first industrial applications of highly interlocking artificial blocks, CLAS has been involved in analysing the actual behaviour of armour layers during construction and after commissioning, by identifying the mechanisms leading to non-conformities, block displacements or block breakage.

Today, CLAS relies on a team of full-time specialised inspectors, trained in the detection, analysis and correction of installation defects of artificial concrete armour units, both above water and underwater. This operational expertise makes it possible to address risk studies with a detailed understanding of the geometric, hydraulic and construction constraints specific to single-layer armour breakwaters.

A methodology based on direct, real-world observation of the structures

Contrary to approaches based exclusively on theory or on numerical models, the risk studies carried out by CLAS are based on direct observation of breakwater armour layers made of artificial concrete blocks, under their real conditions of installation and operation.

On-site inspections, both underwater and above water, make it possible to analyze the actual behavior of the blocks after placement: bearing quality, real interlocking, stress concentration zones, interactions with the underlayer and the toe berm. These determining factors cannot be reliably assessed on the basis of design documents alone.

Physical model tests in wave basins remain essential for understanding global hydraulic mechanisms, but they present a major limitation: under controlled laboratory conditions, blocks do not break. They therefore do not allow anticipation of risks related to concrete failure, load transfer between blocks, or the progressive development of non-conformities observed in the field.

The CLAS approach specifically aims to bridge this gap between theory and on-site reality by integrating experience gained from armour layers built with different types of artificial concrete blocks, in a wide range of geographic, climatic, and operational contexts.

Operational value of risk studies

Why risk studies are an essential decision-making tool for single-layer breakwaters

In a single-layer breakwater project built with artificial concrete blocks, the contractual objective is generally clear: zero risk.

In theory, this would imply that no non-conformity is acceptable.

In practice, this approach is unrealistic.

Any detailed inspection of a single-layer armour reveals deviations, whether real or assumed, whose severity depends on:

local geometry,

the quality of bearing on the underlayer,

the actual level of interlocking,

and the hydraulic exposure of the area concerned.

Without a structured risk study, these deviations may lead either to:

unnecessary and costly remedial works,

or, conversely, to an underestimation of critical defects that could compromise the stability of the structure.

The CLAS risk study makes it possible to objectively rank non-conformities, to identify those requiring immediate action, and to distinguish tolerable defects from those that are not.

It therefore constitutes an operational decision-support tool, usable by:

the owner,

the Engineer in charge of design, construction supervision and works acceptance,

and the maritime construction company,

to secure technical choices, control schedules, and preserve project profitability, while remaining fully compliant with best practice rules applicable to single-layer breakwaters built with artificial concrete blocks.

Real-world example of a risk analysis on a single-layer armour layer

From defect identification to confirmation of the actual risk

The value of a risk study on a single-layer breakwater built with artificial concrete blocks becomes fully apparent when it is confronted with real construction site situations.

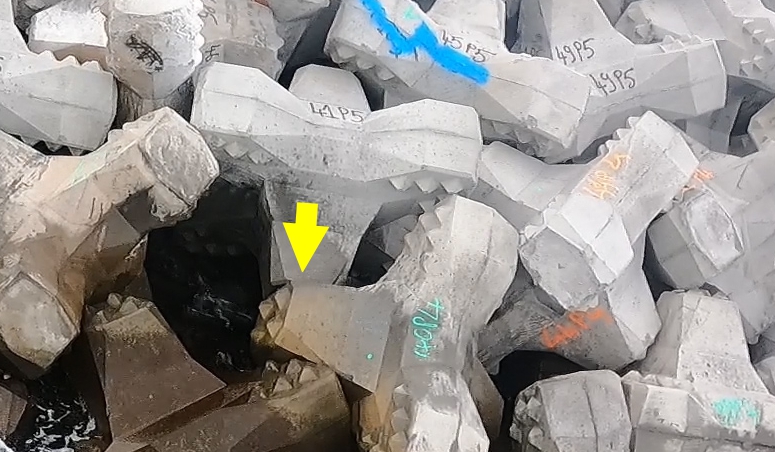

During a detailed inspection of a single-layer armour layer, CLAS identified an artificial concrete block whose nose was partially resting on the inclined surface of an adjacent block, outside the expected interlocking configuration.

This type of positioning, although it may appear acceptable at first glance, introduces a potential sliding and load concentration mechanism, likely to evolve under wave action.

The analysis carried out by CLAS classified this non-conformity as risk level 1:

isolated defect,

possible evolution,

uncertain short-term impact,

but requiring immediate correction while remedial means were still available on site.

This analysis was based on:

direct observation of the actual interlocking,

assessment of bearing conditions on the underlayer,

and experience gained from hundreds of single-layer armour layers exposed to wave action.

In the absence of adjustment of the block concerned, a low-intensity storm was sufficient to cause the actual breakage of the block, retrospectively confirming the validity of the initial risk diagnosis.

This example illustrates an essential point:

👉 risk cannot be assessed solely on the basis of geometric or numerical criteria, but through a detailed understanding of the stability mechanisms specific to single-layer armour layers made of artificial concrete blocks.

It also demonstrates that risk analysis must be entrusted to an organization with:

real field experience,

complete independence from the technologies implemented,

and the ability to intervene before defects become irreversible.

Risk studies as a decision-support tool on construction sites

Risk studies applied to single-layer breakwaters are not intended to multiply findings of non-conformity, but to guide rational operational decisions at a time when they are still possible.

On a real construction site, the total absence of defects is a theoretical assumption. In practice, not all defects have the same capacity to evolve into a disorder. The issue is therefore not to identify deviations, but to determine which ones require immediate action, which can be monitored, and which have no real impact on the stability of the structure.

The risk classification developed by CLAS makes it possible:

to prioritize non-conformities according to their potential for evolution,

to arbitrate between immediate correction, monitoring, or no action,

to avoid unnecessary dismantling while preventing serious degradation,

to secure the decisions of the owner and the contractor.

Risk studies thus become a construction site management tool, linking field observation, best practice rules, and real economic constraints, within a logic of risk control rather than purely theoretical compliance.

CLAS classification of risk levels

The CLAS methodology is based on a classification of non-conformities according to their actual impact on the stability and durability of single-layer armour layers.

This classification distinguishes four risk levels:

🟢 Level 0 — isolated defect with no possible impact on stability; no action required.

🟢 Level 1 — isolated defect that may evolve without immediate serious consequences; correction or monitoring.

🟠 Level 2 — defect presenting a risk of rapid evolution or serious consequences; mandatory correction.

🔴 Level 3 — grouped or interconnected defects leading to a structural disorder; reconstruction of the affected area.

This approach makes it possible to objectify the analysis of non-conformities and to adapt technical decisions to the actual severity of the situations observed on the structure.

A methodology now integrated into procurement contracts

The risk levels defined by CLAS have been applied on numerous port and coastal projects in France and internationally.

Following significant feedback from recent structures, tender documents now explicitly include the requirement to classify construction defects according to their risk level, in order to condition works acceptance and define the appropriate course of action during the construction phase.

This evolution reflects a collective awareness: the stability of single-layer armour layers cannot be assessed through a purely binary approach, but requires a graded technical analysis, based on field experience and established best practice rules.

Excerpt from the Technical Specifications (CCTP): Argelès-sur-Mer Breakwater

“Following its control and inspection activities, the contractor shall submit to the owner a report comprising a quality assurance file, based on the procedures and reference documents approved by the Engineer in charge of design, construction supervision and works acceptance.

The reference framework shall include a classification of construction defects on a four-level risk scale. The associated risk shall be defined for each defect and for each group of defects. The structure may only be accepted provided that it is free of defects leading to a risk level higher than zero risk.

Best practice rules in this field are set out in the CEREMA Rock Manual (Guide Enrochement), which shall constitute the reference document. However, the block supplier’s reference documentation, typical cross-sections and the CCTP, as well as references to reduced-scale physical model tests, shall be integrated into the reference framework implemented for these controls, without limitation. Any broader technical approach intended to guarantee proper execution of the works and their long-term durability may also be integrated, subject to acceptance by the Engineer in charge of design, construction supervision and works acceptance.”

Recent CCTPs reflect this requirement, making the classification established by CLAS a recognized standard.