Objectively assessing installation and inspection tools for single-layer armour layers

Installation, inspection and control tools play a central role in the construction of single-layer breakwaters built with artificial concrete blocks. Their purpose is to improve placement accuracy, operational safety, and the reliability of technical decisions made during the construction phase.

The rapid evolution of technologies — GPS positioning, 3D acoustic imaging, installation assistance systems, armour layer numerical models — has profoundly changed site practices. However, experience shows that the actual performance of these tools depends strongly on their conditions of use, their domain of validity, and their complementarity with human observation.

At CLAS, the assessment of installation and inspection tools is based on tests carried out under real on-site conditions, rather than on commercial demonstrations or theoretical assumptions. This approach makes it possible to identify the real contributions of each technology, as well as their operational limitations when they are used alone or outside their relevant field of application.

General principle of the CLAS evaluation

Contrary to manufacturers’ marketing claims, CLAS does not evaluate installation and inspection tools on the basis of their theoretical specifications, but on their actual behavior on breakwaters under construction or under repair.

The evaluation criteria focus in particular on:

the tool’s ability to guide placement with accuracy,

the reliability of the information transmitted to operators,

the effective detection of interlocking defects,

the ability to identify block breakage or defective bearing conditions,

the impact on production rates and safety.

This methodology has been applied on numerous port and coastal construction sites, under very different conditions of visibility, wave exposure, and water depth.

GPS positioning: a guidance tool, not a validation tool

The introduction of GPS positioning has represented a major advance for guiding lifting equipment during the placement of artificial concrete blocks. The use of X, Y and Z coordinates derived from placement drawings makes it possible to position the block within the theoretical geometric envelope defined by the project.

However, field experience has quickly shown that GPS alone does not make it possible to guarantee correct interlocking of the blocks. Bearing defects, partial contacts or orientation errors cannot be detected through simple geometric positioning.

Today, GPS is considered an installation support tool, essential but insufficient, which must imperatively be complemented by visual and underwater inspection of the actual interlocking.

ECHOSCOPE®: real-time underwater 3D imaging test

ECHOSCOPE® is a registered trademark and an acoustic tool marketed by CODA OCTOPUS, which is not affiliated with CLAS.

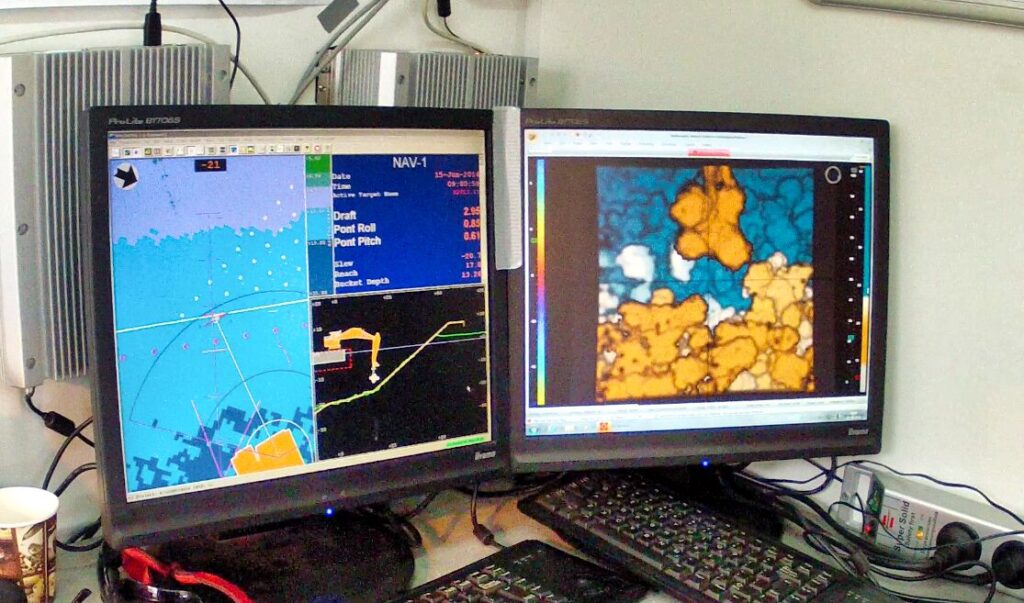

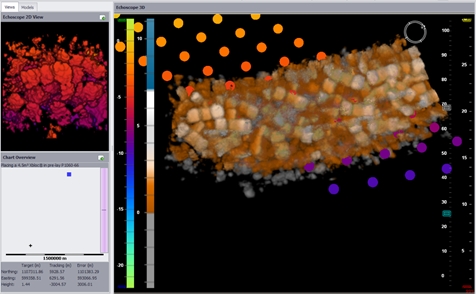

ECHOSCOPE® is a real-time 3D acoustic imaging system designed to visualize the position of the artificial concrete block underwater during the placement phase. It has been used by CLAS on several international projects, notably in Qatar, the United Arab Emirates, Romania, and Central America.

Used as an installation assistance tool, ECHOSCOPE® can improve operational safety, particularly in low-visibility water, and facilitate the crane operator’s work during block lowering.

However, experience shows that the imaging rapidly loses accuracy once the blocks come into contact, due to intrinsic limitations of acoustic wave propagation. The detection of block breakage, actual bearing conditions, and the fine quality of interlocking then remains beyond the tool’s capabilities.

Observed limitations of the ECHOSCOPE®

ECHOSCOPE® is a registered trademark and an acoustic tool marketed by CODA OCTOPUS, which is not affiliated with CLAS.

ECHOSCOPE® is a real-time 3D acoustic imaging system designed to visualize the position of the artificial concrete block underwater during the placement phase. It has been used by CLAS on several international construction sites, notably in Qatar, the United Arab Emirates, Romania, and Central America.

Used as an installation assistance tool, ECHOSCOPE® can improve operational safety, particularly in low-visibility water, and facilitate the crane operator’s work during block lowering.

However, experience shows that the imaging rapidly loses accuracy once the blocks come into contact, due to intrinsic limitations of acoustic wave propagation. Detection of block breakage, actual bearing conditions, and the fine quality of interlocking then remains beyond the scope of the tool.

POSIBLOC™: field feedback and experience

POSIBLOC™ is a registered trademark marketed by MESURIS, which is not affiliated with CLAS.

The POSIBLOC™ system, based on real-time numerical reconstruction of block positions, has been evaluated by CLAS on several international projects.

Field feedback has highlighted recurrent discrepancies between the numerical representation displayed and the reality observed underwater, particularly with regard to block contacts and the quality of interlocking.

On certain projects, these divergences have led to significant interlocking defects and major remedial works, requiring in-depth underwater inspection and manual corrections.

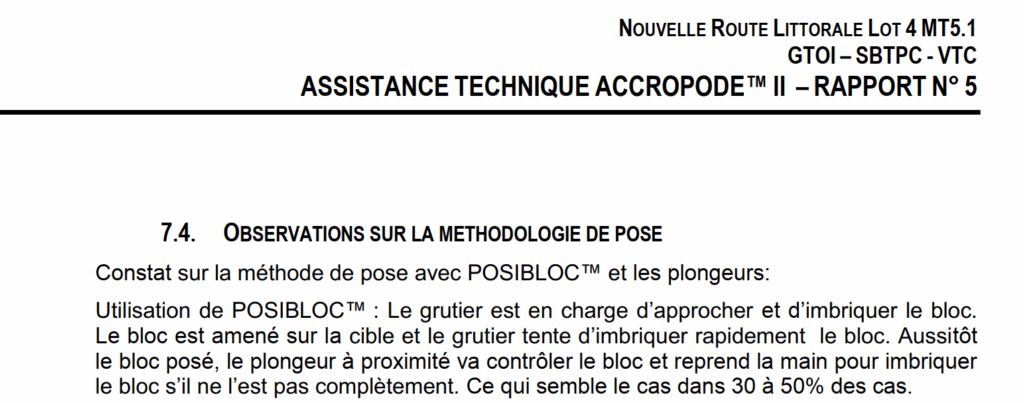

In its site visit reports on the NRL project, the system license vendor reported these issues.

Nouvelle Route Littorale – Lot 4 MT5.1

GTOI – SBTPC – VTC

ACCROPODE™ II TECHNICAL ASSISTANCE – REPORT No. 5

7.4. OBSERVATIONS ON THE INSTALLATION METHODOLOGY

Findings regarding the installation method using POSIBLOC™ and divers:

Use of POSIBLOC™: the crane operator is responsible for approaching and interlocking the block. The block is brought to the target position and the crane operator attempts to interlock the block quickly. As soon as the block is placed, the nearby diver checks the block and takes over to interlock it if it is not fully interlocked, which appears to be the case in 30 to 50% of situations.

Interlocking defects in 30 to 50% of cases are consistent with the issues encountered when installation relies on GPS alone.

Despite this finding, POSIBLOC™ was implemented on the PORT-LA-NOUVELLE site, with full-time assistance from the company MESURIS. This led to CLAS being called in on this project to install the ACCROPODE™ II units with its own divers, first on an emergency basis on the offshore breakwater, and then on the South breakwater the following year.

I would like to reiterate that ACCROPODE™ is a registered trademark owned by the ARTELIA Group, and that POSIBLOC™ is a registered trademark of the company MESURIS; neither of these entities is in any way affiliated with CLAS.

The following photograph shows the definitive removal of the POSIBLOC™ system from the PORT-LA-NOUVELLE construction site.

Our assessment of POSIBLOC™

Feedback from various construction sites, including the most recent one at PORT-LA-NOUVELLE, leads us to exercise the greatest caution regarding this tool. In addition to the very low average production observed on the NRL breakwaters, the recurrent interlocking defects make it unsuitable for the level of precision required for the interlocking of single-layer artificial concrete blocks used in maritime breakwater armour layers.

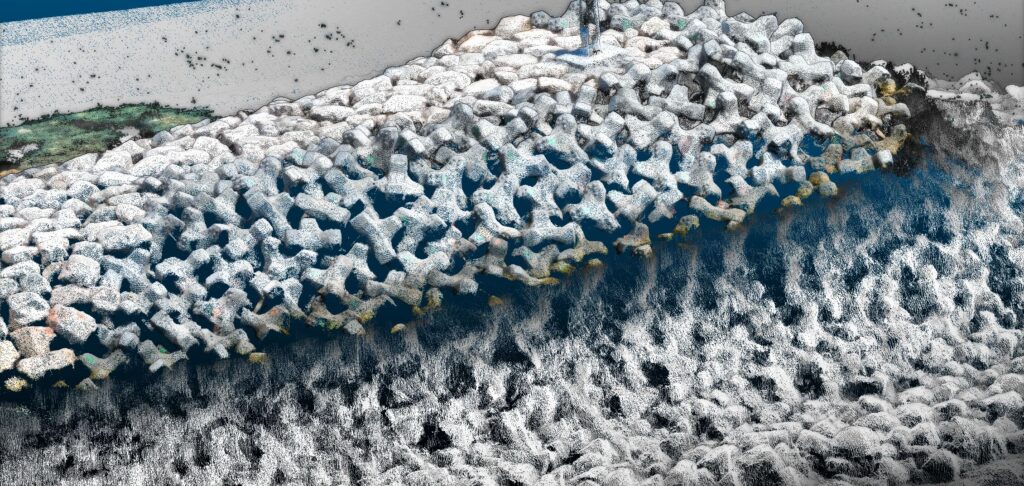

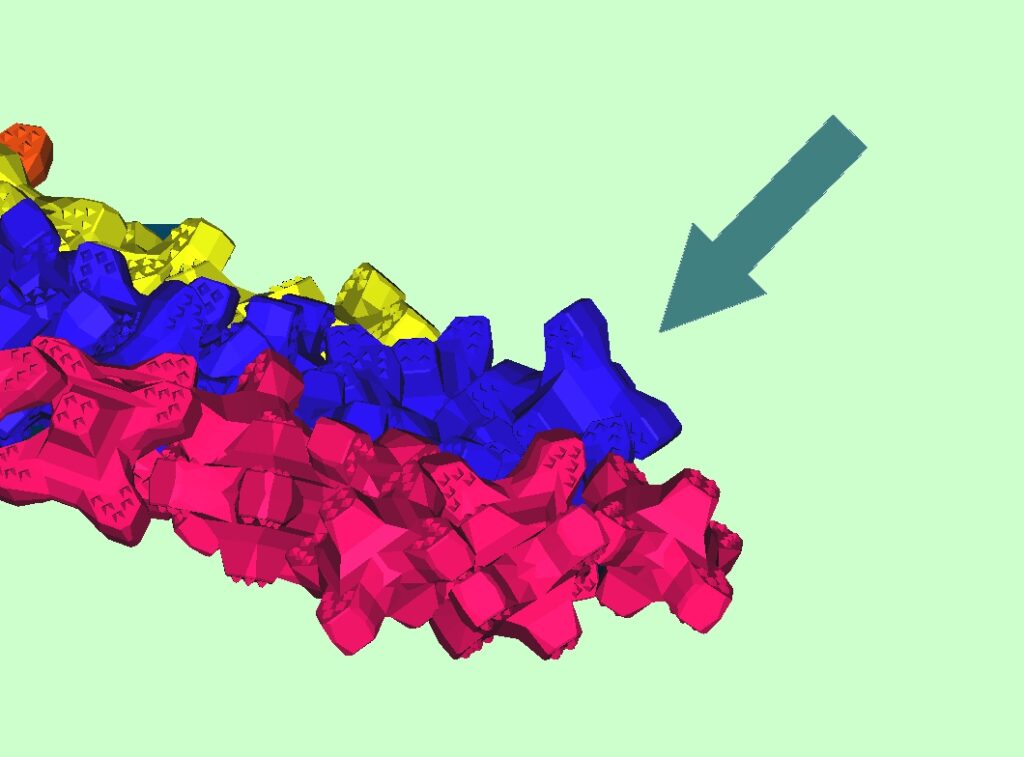

Numerical reconstructions of breakwater armour layers

Numerical reconstruction of breakwater armour layers is the latest technology trend. It appeals to engineers in charge of design and works acceptance as well as to owners, because it allows the image to be manipulated in three dimensions with very high-quality visual rendering.

As was previously the case with GPS technologies, ECHOSCOPE® and POSIBLOC™, the fact that this technology is new and modern leads many to attribute to it all possible virtues. Yet, like all other tools, numerical models have limitations, which we have specifically studied and assessed.

Study of the numerical model known as SEABIM on the NRL breakwaters

On the NRL breakwaters, the Engineer in charge of design and works acceptance, EGIS, sought to determine whether the numerical reconstruction produced by this system was sufficiently consistent with reality to supervise the reconstruction works of the breakwater armour layers.

EGIS developed a specific procedure, the execution of which was entrusted to CLAS. All operations were fully recorded on video. Based on measurements carried out in very clear water and on a direct comparison between the real structure and its virtual representation, this procedure was conducted under the constant supervision of EGIS.

The study concluded that the visual similarity was impressive.

However, distance measurements and interlocking checks revealed discrepancies of up to 17 centimetres, which is excessive to provide a formal opinion on a non-conformity or to validate correct block interlocking.

As a result, EGIS maintained underwater inspection controls carried out by divers.

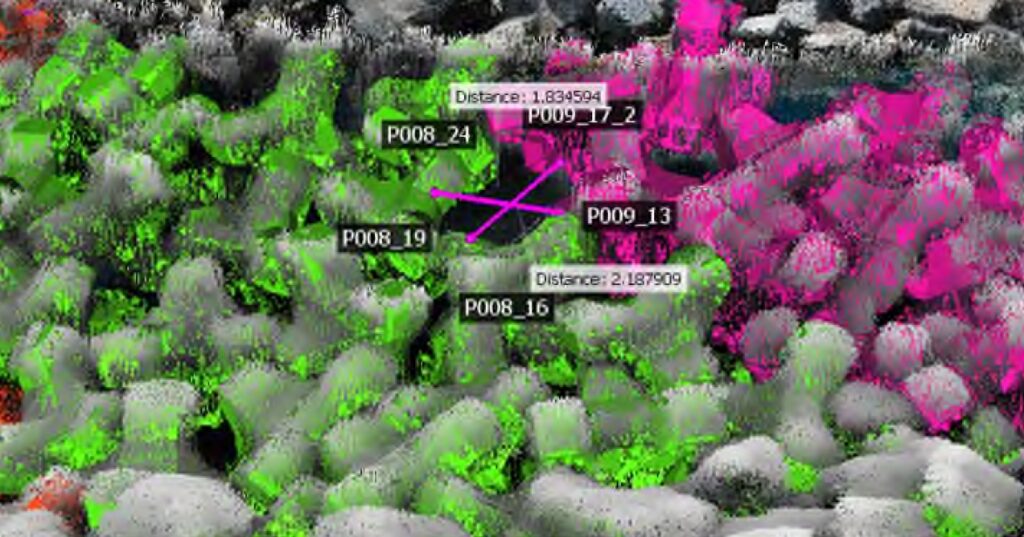

Study of the numerical model known as SEABIM on the Port Gardian breakwater

In the Rhône delta, underwater visibility is rarely good. The Engineer in charge of design and works acceptance, EGIS, sought to compensate for the lack of high-quality video images by using a numerical reconstruction of the armour layer.

The result was alarming and indicated major non-conformities that called into question the stability of the structure. We carried out an underwater inspection by divers and invalidated all technical opinions derived from the numerical model.

This experience showed that a major limitation of this tool is determined by in-situ conditions. Water loaded with suspended particles, wave action and air emulsions produced this type of multibeam sonar survey from which the numerical model is generated.

The upper part of the image is surveyed using LiDAR, a laser system mounted on an aerial drone. No non-conformities appear in this survey, which is relatively clear and accurate.

Underwater, however, nothing can be distinguished between 0 and −4 metres. The shape of the blocks can be vaguely identified around −4 to −5 metres, but beyond that, the rock armour of the toe berm covering the foot of the armour layer prevents any visibility of the artificial blocks.

The non-conformities reported on the basis of the numerical model were located precisely within this blind zone of the sonar. For example, in the following image, the numerical model highlights a block of which at least three quarters of the volume are shown as protruding from the armour layer. It would not be out of profile, but supposedly placed in a second layer.

The underwater inspection carried out by divers showed that this block does not exist. It is the result of an artefact caused by the dispersion of the sonar’s acoustic waves.

This phenomenon has also been identified when using ECHOSCOPE® and the DIDSON and ARIS acoustic cameras.

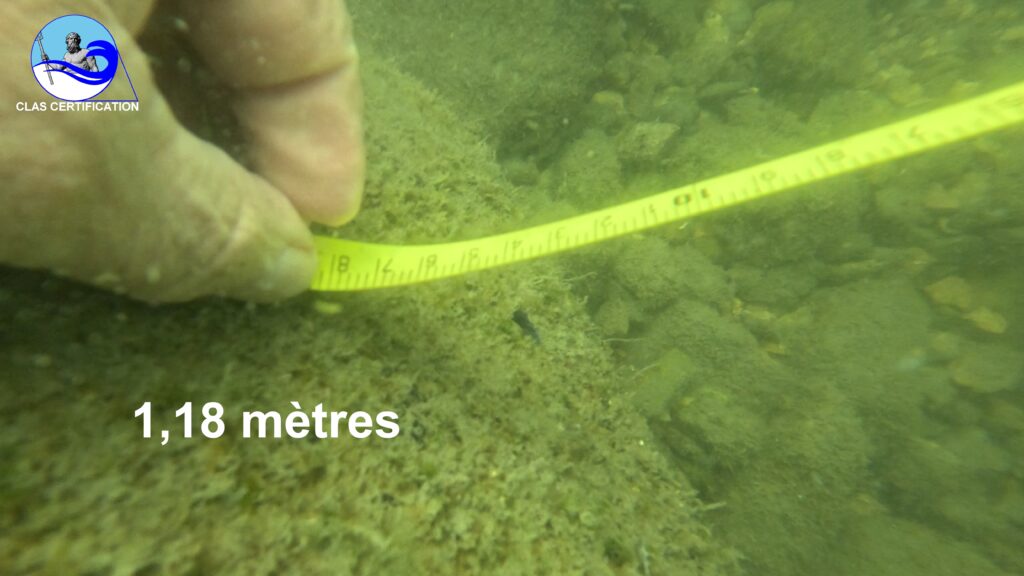

Further along the same structure, a void exceeding 2 metres was indicated on the numerical model. The largest measured value shown is 2.187909 metres.

We measured this opening by diver inspection, which represents the largest distance that can be measured for this void, and found a value of 1.18 metres.

Our assessment of numerical models

The tool remains of interest for carrying out a survey of the armour layer at the end of the construction phase, once the structure has been certified using reliable techniques. Any non-conformities or pathologies highlighted must be verified by experienced divers.

This implies that areas validated solely on the basis of this tool may not actually be compliant, or conversely that reported non-conformities may not exist. In all cases, an evaluation of the tool is recommended prior to use, as the results can vary significantly depending on the conditions under which the sonar producing the point clouds is deployed.