SINCE 2009 WE OFFER QUALITY CERTIFICATION

CLAS inspectors apply a certification procedure which is currently based on two types of standards:

Type 1 technical documents:

The CLAS inspectors have access to the CLAS repository resulting from more than twenty years of experience in the construction, repair and expertise of shells using the TETRAPODE, ANTIFER, ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™ , Xbloc® and more.

Thanks to the CLAS repository, we have been able to help companies to complete the works on which we have worked on time, without reservations upon receipt and without conflict.

The CLAS BREAKWATER SOLUTION™ repository complements and improves the TECHNICAL INFORMATION DOCUMENT issued by Concrete Layer Innovation for the ACCROPODE™, ACCROPODE™II, CORELOC™ and ECOPODE™ contracts.

As well as the document entitled: SPECIFICATIONS FOR THE USE OF XBLOC issued by delta Marine Consultants for X-bloc® contracts.

It enables all types of block to be placed quickly and correctly, even in the absence of another reference system.

Type 2 the design:

The designer defines the profiles and construction plans as well as the qualities of materials that must be implemented.

It is not uncommon for there to be contradictions between the design and the requirements of Concrete Layer Innovation or Delta Marine Construction. CLAS inspectors know how to highlight contradictions and help you to find a solution.

We can also advise the designer on the practical difficulties that will arise during construction in order to anticipate them through a design consistent with the reality of an armour construction using the ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™, Xbloc®, BS1, BS2, BS3 blocks.

THE CERTIFICATION PROCEDURE

The objective is to be able to deliver to the client or the contractor, a report of inspection which specifies that the built construction is technology compliant. A certificate of conformity to the ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™, Xbloc®, BS1, BS2, BS3 confirmed by the registered trademark CLAS TECHNOLOGY COMPLIANT™ recognizable by this stamp:

Step 1 Study the profiles

The profiles tell us the nature of the materials and the theoretical depth to which they must be found. They define the thicknesses of these materials. This is the reference set by the designer.

CORELOC ™ armour profile

Study 2 The placement drawings

The installation plan tells us if there is a peculiarity on the laying area, such as a rapid change of depth or the connection between two block sizes, for example.

ACCROPODE ™ II placement drawing

Placing drawings are provided by the licence vendors. CLI draws up the placing drawings for ACCROPODE™, ACCROPODE™II and ECOPODE™ blocks.

Delta Marine Consultants draws up the placing drawings for X-bloc ® and X-bloc+ ®.

CLAS draws upplacing drawings for blocks that are not subject to licence such as BS1, BS2, BS3 and other blocks whose patent has fallen into the public domain and which are not implemented as part of a paying brand.

Step 3 The repositories

TID can evolve from year to year depending on advances in technical knowledge and feedback. CLAS uses the TID of your project.

CLAS also has its repository resulting from more than 20 years of implementation of the TACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™, Xbloc®, BS1, BS2, BS3 blocks which supplement or replace, if necessary the documents provided by the license vendors.

Step 4 The inspections

Being an inspector cannot be improvised. It is a profession in its own right that can be learned. Being a professional diver is not enough, but it is essential. An inspector must be rigorous, critical, have a sense of observation and authority.

4-1 Inspection of the horizontal berm and the underlayer

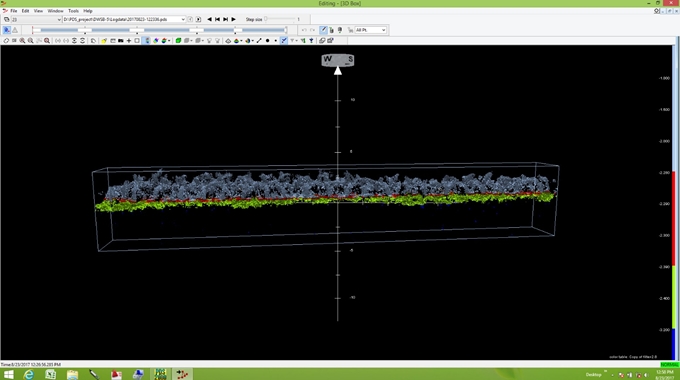

Inspection using a multibeam echo sounder showing the profile perfectly within +/- 0.2 meter tolerances and approved by the company and customer survey department

CLAS inspection on the same profile showing gaps and protruding rocks on an irregular profile de + or – 1,7 meters and more exactly on the same profile.

This is not an extreme case and it is not uncommon. The underlayer does not conform to design or technology. The installation of the TETRAPODE, ACCROPODE™, ACCROPODE™II, ECOPODE ™, CORELOC™, X-bloc®, BS1, BS2, BS3 blocks, which must comply with the tolerance rules of the underlayer as defined in their respective TID, is not possible. This marks a stop point. CLAS inspectors produce a video with measures to justify their decisions.

When the underlayer and the horizontal berm are approved the placement of ACCROPODE™, ACCROPODE™II, ECOPODE ™, CORELOC™, X-bloc®, BS1, BS2, BS3 blocks is allowed.

Technology Compliance Report for ACCROPODE™II underlayer

The ACCROPODE™, ACCROPODE™II, ECOPODE ™, CORELOC™, X-bloc®, BS1, BS2, BS3 blocks are checked several times a day to limit disassembly.

Inspection of an ACCROPODE™II armour and evidence of bad interlocking of one ACCROPODE™II

When the placement is TECHNOLOGY COMPLIANT the ACCROPODE™II armour is filmed

The contractor must then place the toe mount protection before building the armour out of the water. As long as the underwater armour is not properly wedged by the toe mount, the ACCROPODE™, ACCROPODE™II, ECOPODE ™, CORELOC™, X-bloc®, BS1, BS2, BS3 blocks are suspended.

The contact between the toe mount and the armour blocks is controlled and filmed.

When the toe mount is in place, ACCROPODE™, ACCROPODE™II, ECOPODE ™, CORELOC™, X-bloc®, BS1, BS2, BS3 can be placed out of the water.

The construction out of the water is the subject of the same attentions as the construction under the water. CLAS inspectors conduct a walking tour that is essential and a drone inspection.

CLAS inspector on an ACCROPODE™II armour

The walking tour is completed by a drone inspection. CLAS has developed a special procedure for the use of the drone, which allows us to collect all the information that the walking tour does not give.

X-bloc® inspected by drone

When the carapace is technically compliant, the crest can be laid and inspected in the same way. Non-compliance marks a stopping point.

Drone inspection of an ACCROPODE™II armour crest

Each step of the construction that marks a stop point in the event of non-compliance gives rise to an inspection report. Once the various construction steps have been approved and the proof of compliance established, the CLAS inspector drafts the Technology Compliance Report.

Example de TCR established for an X-bloc® armour

When all stages of construction are completed, from the foundation of the work to the crest, CLAS hands over to the owner or his representative, the complete final document no later than one week after the end of the construction.

All quality assurance documents prepared by CLAS inspectors are updated in real time on site during construction. CLAS's intervention generates no delay in decision making and no delay in payment for the contractor.

The certification procedure put in place by the CLAS inspectors provides the certainty of having ACCROPODE™, ACCROPODE™II, ECOPODE ™, CORELOC™, X-bloc®, BS1, BS2, BS3 CLASS A

ADDED VALUE OF OUR CERTIFICATION

The durability of an ACCROPODE™, ACCROPODE™II, ECOPODE ™, CORELOC™, X-bloc®, BS1, BS2, BS3 armour is defined by the designer. It is acquired when the design is respected and when particular care is taken in the construction of the armour and its underlayer, to correspond at least to the 3D reduced model. The criteria for accepting the armour must be met without exception.

They are defined by the technical specifications issued under the license agreement. By CLI for ACCROPODE™, ACCROPODE™II, ECOPODE™ and CORELOC™ blocks. By DMC for X-bloc®.

The means implemented to ensure that these criteria are met must enable non-compliances to be identified without exception.

Exception to this rule can lead to localized or significant disorders. Repairs often by sea will be very expensive.

In extreme cases, the design is not respected in order to increase the profit margin by saving on materials.

Installation of ACCROPODE™II without underlay, directly on the core. The toe and the first line left very quickly.

Companies can easily make false profiles by using a multibeam sounder whose data are easily modifiable:

Project with multibeams

Inspection on the profile approved using tolerances + or – 0,4 meter.

On another project the multibeam survey of the profile was perfect:

In reality we measure holes of 1.7 meters and more for a tolerance of + or - 0.3 meters.

The data produced by the multibeam can be easily distorted to present acceptable profiles in place of a completely out-of-tolerance underlayer.

Placing tools have limitations that salers do not indicate

ECHOSCOPE®

On DAS ISLAND ECHOSCOPE® was used to place the X-bloc® and to approve the underwater work. Major disruptions that occurred after the approval led CLAS inspectors to put in place a certification procedure for the reconstruction of 5000 meters of X-bloc® armour.

Clic on the link to see the video of DAS ISLAND: https://youtu.be/OROspj0EB1Y

On Puerto Moin, VAN OORD, a highly experienced and more cautious company, asked CLAS to evaluate the latest version of the ECOSCOPE® that was planned to approve the X-bloc® installation work. We conducted two evaluations: at the beginning of the project and after six months of use with the same operators. We made an inspection with good visibility on X.bloc® approved by ECHOSCOPE®.

The figure below summarizes the conclusions of our report after six months of training operators:

On the other hand, all the comparative tests carried out on the ECHOSCOPE® installation up to and including 2016 conclude that the system sometimes highlights non-conformities that do not exist and does not reveal non-conformities that exist. It is due to the mask effect that concerns the acoustic tools even the finest as the ARIS acoustic camera that we tested in 2016. At Puerto Moin we also brought the proofs that nonconformities highlighted by ECHOSCOPE® images did not exist in reality.

Clic on the link to see the video: https://youtu.be/XZ3UmmlpMMA

Clic on the link to see the video about the evaluation: Placing tools ECHOSCOPE®

We cannot use the images produced by the ECHOSCOPE® to certify the quality of the construction

The POSIBLOC™

At RAS LAFFAN 2008 with ACCROPODE™ 4 m3 and at KHALIFA in 2009 with ACCROPODE™ 0.8 m3, the system did not work.The tests concluded that the system should be stopped despite the increased assistance provided by MESURIS.

In BARAKAH in 2013 with CORELOC™ of 2 m3 the system was stopped by NMDC and KEPCO Korean company in charge of building the ABU DHABI nuclear power plant. The system did not work satisfactorily.

Clic on the link to see the video: https://youtu.be/OyuoV07hx1g

Clic on the link to see the video about the evaluation: Placing tools POSIBLOC™

The system as we saw it in 2017 on ALFAW is improved compared to the previous experiences that we had, so far the precision limited to + or - 0.15 meter generates discrepancies between reality and computer image, in particular by signaling missing contacts while these contacts exist, which led to CORELOC™ breakages in trying to adjust the placement. The system also signals established contacts which in reality are not, causing undetectable contact faults on computer generated images or on acoustic tools fixed on a frame. Out of profiles and holes are not correctly identified and again nonconformities that do not exist are reported by the software. The production is limited to 3 or 4 units per hour and this pose has not been validated and required repairs.

Click on the link to see the video of evaluation https: //youtu.be/gFVVIZo4Wak

We cannot use the images produced by the POSIBLOC™ and its software VISIBLOC™ to certify the quality of the construction

Divers must also be checked and the procedures they apply validated by specialists in the armours inspection for ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™, X.bloc®, BS1, BS2, BS3

On one project we found that the divers of the company who supervised the ACCROPODE™ installation used the video of an approved ACCROPODE™ panel to film it from different angles and present the single panel video as different panels, in order to mask major nonconformities. We put an end to it.

Click on the link: Placing tools

CLAS implements a simple and efficient tool evaluation procedure for the approval of ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™, X.bloc®, BS1, BS2, BS3 armors.

An ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™, X.bloc®, BS1, BS2, BS3 armour may be approved if the acceptance criteria are met.

Validation of inspection tools

The validation procedure of an inspection tool for approval consists of an inspection with this tool and an inspection carried out in good visibility conditions by a CLAS inspector. Both inspections must show the same non-conformities.

The ARIS acoustic camera

The ARIS Acoustic Camera offers unsurpassed acoustic image quality. CLAS tested it with the Underwater Acoustics Laboratory of the University of Girona in May 2016. The images are of better quality than those obtained with the DIDSON camera in 2009 on the same structure.

The important disorders are clearly visible, not the nesting defects, nor the outside profiles and the holes are difficult to appreciate. The fixed frame was equipped with a rotator to vary the inclination but this was not enough to reduce the mask effect which limits the nature and quality of the information collected and does not allow it to be used to control the shell acceptance criteria. It cannot be used to validate an installation for a class A structure. The ARIS camera is now available in a diver version, which should allow dynamic inspection to be carried out by highlighting all non-conformities even with zero visibility. We have to test it.

ECHOSCOPE®

The holes shown in this image do not exist.

Conversely, actual non-conformities may not be identified.

X-bloc® broken and badly nested not identified on the ECHOSCOPE®

Multibeam sonars

The quality of the image varies greatly depending on the model

At best we are faced with the same limitations as with the ECHOSCOPE®. These tools can be used to survey the outer shell of the shell, not to make an approval confirming that the acceptance criteria are in place. The diffraction of the acoustic signal due to the design of the ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™, X.bloc®, BS1, BS2, BS3 blocks is too great. The mask effect is too strong.

In addition to the mask effect, the context of the project, presence of swell, depth, size of the blocks used are all factors that influence the ability of a tool to deliver information.

These tools can be used to survey the outer shell of the shell which will be attached to the as built.

All of these tools are evolving and the certification procedure put in place by CLAS inspectors allows companies and customers to know what the real possibilities of each tool are in the context of their projects.

Useful link: http://www.clasexpertise.com/_img/_public/pdf/1_22_Procdure_de_certification.pdf

RISK LEVELS

The founder of CLAS was a commercial diver when the first breakwater using ACCROPODE™ was built in Sète where he worked. He was the first and one of the only experts in the world in charge of the complete expertise of breakwaters built with ACCROPODE™ and who experienced major disorders from 2000 to 2007. Since 2008 he works as an expert and consultant on the biggest projects in the world using ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™, X.bloc®, BS1, BS2, BS3 technologies.

This unique experience in the world and his professional diving qualities have given him unique opportunities to observe the movements of the blocks in the water, to study the consequences and understand the mechanisms of destruction.

.jpg)

From this exclusive experience based on the observation of the ACCROPODE™, ACCROPODE™II, CORELOC™, ECOPODE™, X.bloc®, BS1, BS2, blocks in real conditions and not only in the laboratory, he has been able to develop a classification of the risks related to non-conformities during the construction.

This assessment has been taken up and shared by Concrete Layer Innovation on ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ and Delta Marine Construction projects on X-bloc® projects.

|

Level of risk

|

Action |

|

0 |

No action |

|

1 |

Local default needs to be monitored |

|

2 |

Local repairs |

|

3 |

Area needs to be rebuilt |