REALIZATION OF THE PLACING DRAWINGS

This service is intended exclusively for companies that have signed the BREAKWATER SOLUTION™ agreement and have an assistance contract with CLAS.

Since single-layer artificial blocks, like the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ , X-bloc ®, BS1, BS2, BS3 types have existed, the way of establishing the placing drawings has evolved. CLAS is the only company that provides a full-time presence on your sites. For more than twenty years we have been the privileged witnesses of these developments, of the real or supposed added value of the placing drawings and the difficulties sometimes in applying it to the real construction.

Thanks to this experience by your side, CLAS has acquired a high level of expertise in the development and optimization of placing drawings, which gives priority to the greatest possible stability of artificial blocks, like the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ , X-bloc ®, BS1, BS2, BS3 .

We have formed a dedicated team that combines draftsman and field staff.

From our offices connected by very high speed to the whole world or from your site facilities, you do not wait for your placing drawings, we are extremely responsive. We have the ability to carry out the placing drawings on the construction site, in real time, on the first request, when necessary.

Some useful information for the proper use of the placing drawings

Is a placing drawing essential?

Yes. All highly interlocking blocks like the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ , X-bloc ®, BS1, BS2, BS3 , will produce shells of extremely solid breakwaters if their interlocking is perfect and strong. To achieve this objective, it is absolutely necessary to perfectly position the first line of artificial blocks, at the right distance between them and following an excellent alignment. This good position of the first line is given by the laying plan. The laying of the artificial blocks of the first line will guide the laying of the following blocks. A block that fits between two blocks in the bottom row.

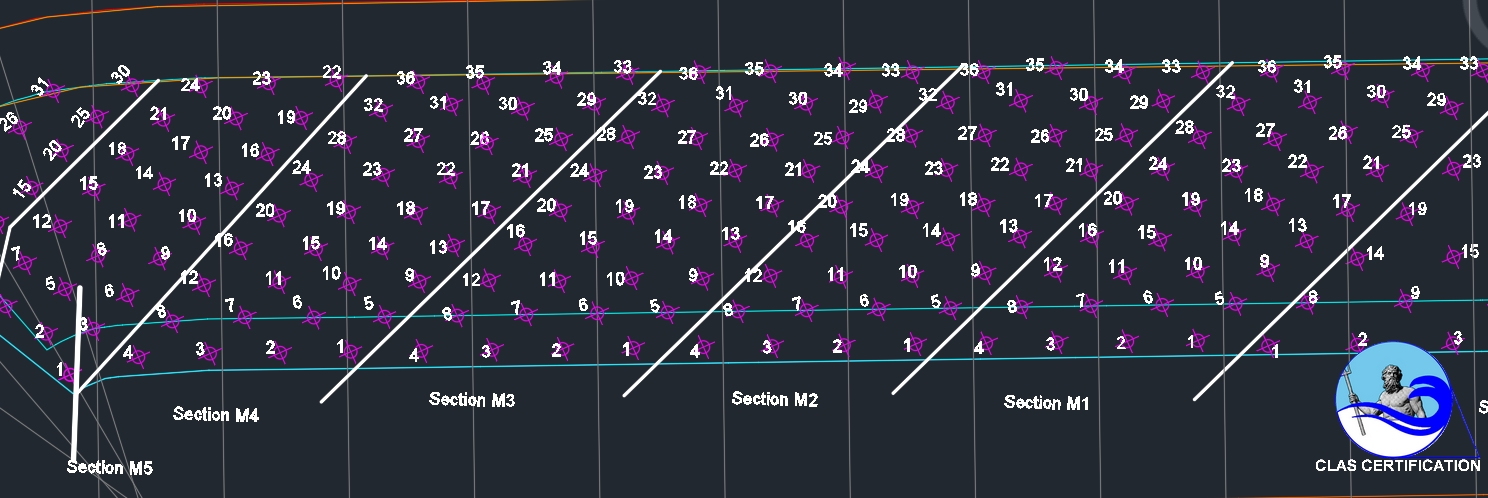

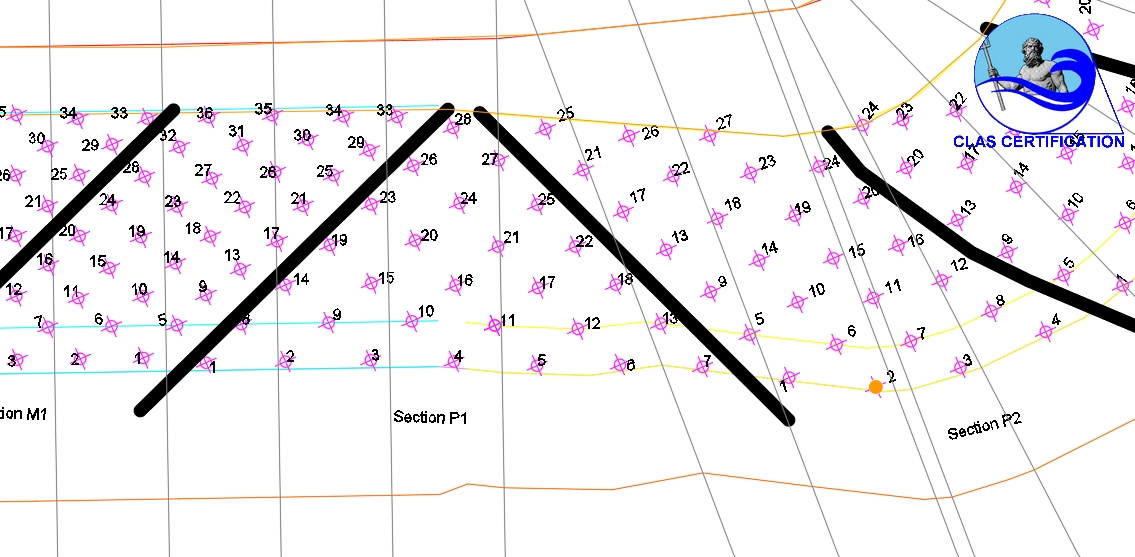

Looking in more detail at the laying plan, you can see the diamond mesh, which automatically results from the positioning of an ACCROPODE™II block or other, between two of the lower row.

This principle applies to all single-layer, highly interwoven artificial blocks like the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™, X-bloc®, BS1, BS2, BS3 .

The placement of artificial blocks always begins with a first triangle. We position it where it is most relevant to do so. It is generally the company that decides on the start-up area of the work. But we can quickly and simply reposition this first triangle if necessary.

Can we start several triangles at the same time?

Yes. On large structures, several placing teams can work, all building a starting triangle and converging towards each other.

We can see on the KHALIFA construction site in 2009, several barges start placing ACCROPODE™ at the same time, on the same large breakwater.

If the placing drawing has been made correctly and the distance between the artificial blocks of the first line has been respected during construction, there will be no problems in connecting different areas with each other.

Should the survey of the underlay be integrated into the placing drawing ?

No. Experience has shown that this is not necessary. If the tolerances are respected in the production of the foot berm and the underlayer, there is no added value. The Z value in the X,Y,Z position indicates the altitude of the block. It has no use outside of the first line of artificial blocks. It is above all the Z of the foot berm which must be respected and the respect of tolerance in its realization. The artificial blocks of the first line must be perfectly aligned.

This photo shows the perfect alignment of the first row of CORELOC™ at the BARAKAH construction site in ABU DHABI in 2013

Once the first row is correctly placed, the use of the Z Value which indicates the altitude can mislead the installation team, because the perfect interlocking can only be appreciated visually. The theoretical altitude does not help to appreciate this interlocking. An artificial block placed on an slope may remain attached to the slope and slightly touch the lower row. When this happens, the block may later descend under the weight of the upper rows or under the action of the swell and break. If the Z value is entered in the placement coordinates, it will be used to assess the good quality of the placement, by mistake and will be one of the possible causes of settlements and future damage.

The following photo shows an ACCROPODE™II which has not lowered into its final interlocking position, although the theoretical Z value was correct.

The following photo shows an ACCROPODE™II out of profile and poorly interlocked, although the theoretical Z value was correct.

The following photo shows multiple breaks of ACCROPODE™II which have been placed according to a placing drawing and placing tool which incorporates the Z value. We checked the packing density and found that it was correct and included within the tolerances indicated by the TID for ACCROPODE™II.

CLAS has chosen to scrupulously check compliance with tolerances and the roughness of the placing surface, but above all not the Z value of the theoretical laying coordinates of each block. We favor real visual control, of the perfect interlocking of each artificial block.

Is the numbering of each block in the layout plan important?

Yes. This numbering indicates an order in which the blocks are placed. Especially in curved sections, such as roundheads, if this order of placing is not respected, it will become difficult, or even impossible, to place all the blocks in these particular parts. This concerns all single-layer artificial blocks with strong interlocking type ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ , X-bloc ®, BS1, BS2, BS3 .

Is the placing drawing necessary to calculate the packing density?

Yes. The placing drawing establishes the theoretical quantity of artificial blocks to be placed on a given theoretical surface. This quantity must be found more or less on the actual placing slope. The placing drawing is therefore the reference for calculating the packing density.

We nevertheless draw the attention of companies and design offices to the fact that compliance with the theoretical installation density is not a guarantee of the stability and solidity of an armour made of single-layer artificial blocks, with a strong interlocking of the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™, X-bloc ®, BS1, BS2, BS3 . If you place more blocks on the actual slope than on the laying plane, the packing density will be greater than 100%. If you lay less, this density will be less than 100%.

A low packing density will certainly expose the work to a high risk of premature damage.

A packing density of 100% or more is not a guarantee of solidity, it is a criterion that is useful, but is not sufficient on its own.

This principle is applicable to all single-layer artificial blocks with strong interweaving of the ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™, X-bloc ®, BS1, BS2, BS3.

Can we respect the placing drawing without GPS?

Yes. CLAS has developed an placing procedure without GPS which makes it possible to respect the placing drawing. This procedure makes it possible not to stop a site in the event of loss of network, due to war, technical failure or climatic interference. Once the network is restored, the GPS can be used again and the blocks will connect perfectly with those placed according to our procedure. We were already building breakwaters using ACCROPODE™ before GPS existed.

Our procedure is applicable to all single-layer artificial blocks with strong interlocking type ACCROPODE™, ACCROPODE™II, ECOPODE™, CORELOC™ , X-bloc ®, BS1, BS2, BS3.