YEAR: 2012

PROJECT: DAS ISLAND

COUNTRY: ABU DHABI

CONTRACTOR: SIXCO

CLIENT: ADNOC

HISTORY:

SIXCO was to build the extension of the island of DAS and its airport. Before the end of the dam construction work, settlement and breakage of X-bloc ® appeared.

THE KEY NUMBERS:

33 333 X-bloc ® of 3 m3.

THE MISSION :

IDMer, now CLAS, intervened as an independent consultant with the mission:

Explain the reason why these damages.

Suggest solutions for the recovery of non-conformities.

Train installation teams and divers.

Control the work.

Certify the shell's conformity to the DMC design and TID.

PRODUCTION:

We repaired 5,500 meters of shell in less than six months and have shown that X-bloc ® can be adjusted without systematically removing them from the water. 50% of the repairs were carried out without disassembly.

PROCEDURE:

All non-conformities were purged with only 50% dismantling.

The CLAS inspectors intervened full time in order to carry out several daily inspections and thus not delay the work by imposing significant dismantling. The training of diving and non-diving personnel has been continuous in order to maintain the highest level of safety and quality.

At the end of each inspection, a debriefing was organized with the installation team.

The inspections were carried out underwater by IMCA and HSE certified CLAS inspectors, who strictly apply the principles defined in the CLAS TECHNOLOGY COMPLIANT ™ trademark and out of the water by foot and by boat.

The inspections were carried out underwater by IMCA and HSE certified CLAS inspectors, who strictly apply the principles defined in the CLAS TECHNOLOGY COMPLIANT ™ trademark and out of the water by foot and by boat.

RESULT:

RESULT:

The project was delivered on time and the X-bloc ® breakwaters received without reservation by the client.

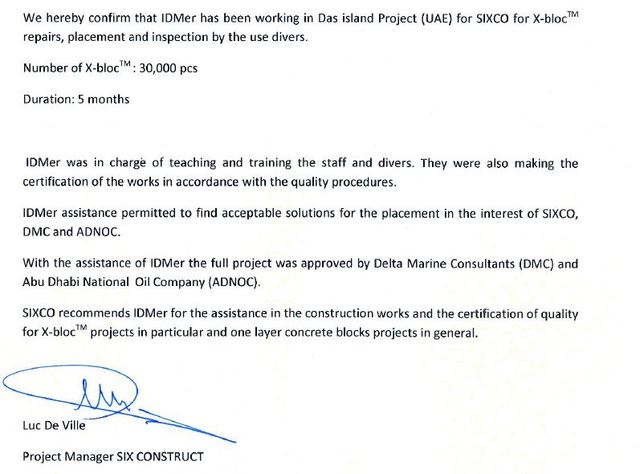

COMMENT FROM SIXCO:

CLAS continues this tradition of excellence and security at the service of your projects