YEAR: 2016-2017

PROJECT: AL ZOUR REFINERY PROJECT

COUNTRY: KUWEIT

COMPANY: VAN OORD

CLIENT: KPNC

HISTORY :

VAN OORD was to build a new port forthe Al Zour refinery in Kuwait.

KEY FIGURES:

KEY FIGURES:

17 000 CORELOC™ 1 m3.

THE MISSION :

CLAS acted as an independent consultant

with the mission:

Train all personnel in specific CORELOC ™ safety.

Train CORELOC ™ laying teams.

Ensure the interface between the company and CLI.

Establish and implement inspection procedures.

Issue quality certification documents CORELOC ™ certification.

PRODUCTION:

Production is calculated on the basis of actual installation hours.

Stoppages due to bad weather, breakdowns and generally causes

unrelated to the installation of CORELOC™ are not taken into

in this calculation.

CORELOC™ 1 m3 : 15 units per hour.

PROCEDURE :

CLAS inspectors intervened full time to carry out several daily inspections and thus not delay the work by imposing significant dismantling.

The training of diving and non-diving personnel has been

continues to maintain the highest level of security and quality.

At the end of  each inspection, a debriefing was organized with the placing team.

each inspection, a debriefing was organized with the placing team.

The inspections were carried out underwater by inspectors fromCLAS IMCA and HSE certified, which strictly apply the principlesdefined in the trademark CLAS TECHNOLOGY COMPLIANT™ and out of the water by foot and boat tours.

RESULT :

The site was delivered in advance and the armor in CORELOC™ accepted without reservation by the client.

CLASS A BREAKWATER certified work by CLAS in accordance the CLAS TECHNOLOGY COMPLIANT™ registered trademark which specifies that independent inspections have confirmed compliance with the design and CORELOC ™ technology.

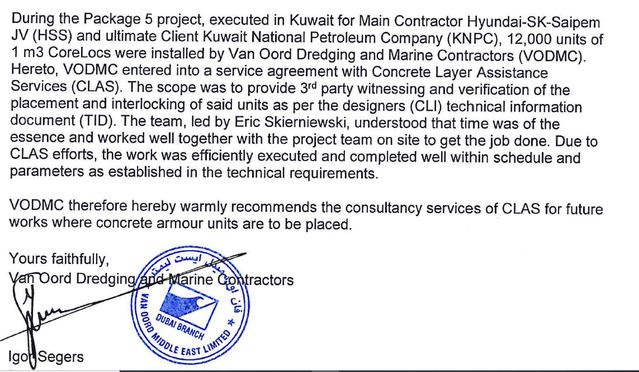

COMMENT FROM VAN OORD :

CLAS continues this tradition of excellence and security at the service of your projects