YEAR: 2015-2019

PROJECT: KUANTAN NEW DEEP WATER TERMINAL.

COUNTRY: MALAYSIA

CONTRACTOR: IJM-CHEC JV

CUSTOMER: ECERDC

HISTORY:

CLAS led the full expertise of the project including respect for the design and ACCROPODE ™ II technology.

CLAS provided ECERDC and CLI with the risk analysis.

The client ECERDC made the decision to replace the first contractor and gave the contract to the Chinese company IJM-CHEC JV.

IJM-CHEC JV was responsible for reconstruction of 3600 meters of breakwater and completing the construction of the remaining 1000 meters to be built.

ECERDC instructed CLAS to reach the quality objectives in order to allow the certification of the project.

KEY FIGURES:

8,616 2 m3 ACCROPODE ™ II.

52 153 ACCROPODE ™ II of 4 m3.

1,364 5 m3 ACCROPODE ™ II.

MISSION:

CLAS acted as an independent consultant with the mission of:

Assess the KUANTAN breakwater and analyze the risk.

Supervise repair and construction work on the ACCROPODE ™ II shell, embankments, berms and toe cap.

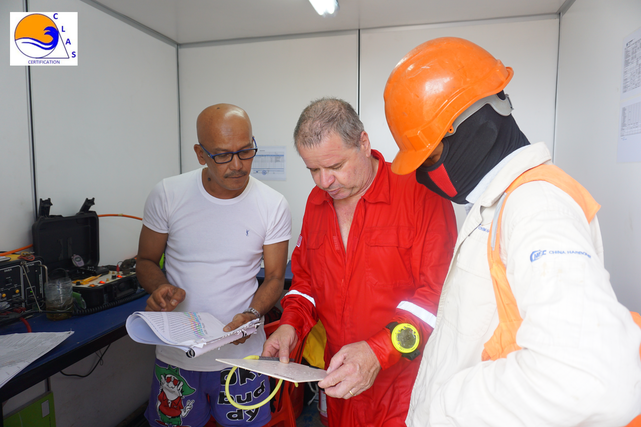

Train staff in specific ACCROPODE ™ II safety procedures.

Train ACCROPODE ™ II placement teams.

Ensure the interface between the client, CLI and the company.

Guide the work of the repair work committee.

Establish and implement inspection procedures.

Produce CLASS A BREAKWATER certification documents and the risk analysis which authorized CLI to issue its certificate of compliance.

PRODUCTION:

Production is calculated on the basis of actual installation hours. Stoppages due to bad weather, breakdowns and generally causes unrelated to the installation of ACCROPODE ™ II are not taken into account in this calculation.

ACCROPODE ™ 2 to 5 m3 in straight section: 6 units per hour.

ACCROPODE ™ 5 m3 in head: 5 units per hour.

PROCEDURE:

CLAS inspectors intervened full time to carry out several inspections per day, so as not to delay the project by imposing major dismantling.

With the agreement of the client, we gave advice and recommendations to IJM- CHEC JV in order to facilitate and accelerate the installation of ACCROPODE ™ II blocks.

After each inspection, a briefing was organized with the installation team.

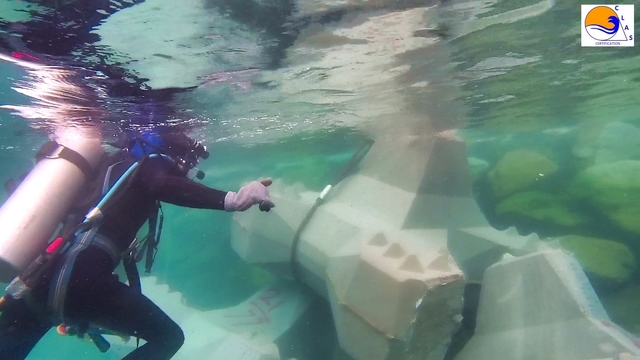

The inspections were carried out underwater by CLAS inspectors who are IMCA and HSE certified, who strictly applied the principles contained in the CLAS TECHNOLOGY COMPLIANT ™ trademark. The out-of-water inspections were carried out on foot and by drone.

RESULT:

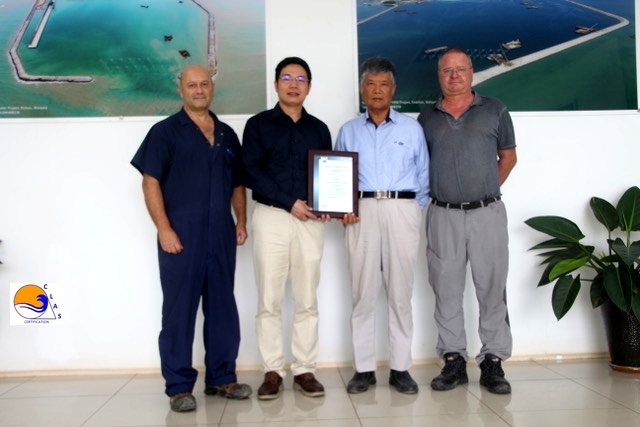

The project was delivered on time and the ACCROPODE ™ shell approved without reservation by the client.

The project is CLASS A BREAKWATER certified by CLAS in accordance with the trademark CLAS TECHNOLOGY COMPLIANT ™ which certifies that independent inspectors have confirmed the conformity of the project with the design design and ACCROPODE ™ II technology.

Assisted by CLAS, the Customer was able to have access to an exceptional work of impeccable quality.

The company IJM-CHEC JV has demonstrated its ability to build an exceptional CLASS A certified structure on time.

ECERDC'S COMMENT:

COMMENTS FROM IJM-CHEC JV:

CLAS continues this tradition of excellence and security at the service of your projects

Video: https://www.youtube.com/watch?v=9HwPdtx1CqY